Compression Molding Plastic Sheets

Molding plastic sheets molding plastic sheets suppliers directory find variety molding plastic sheets suppliers manufacturers companies from around the world at plastic sheets plastic injection molding plastic molding plastic sheets.

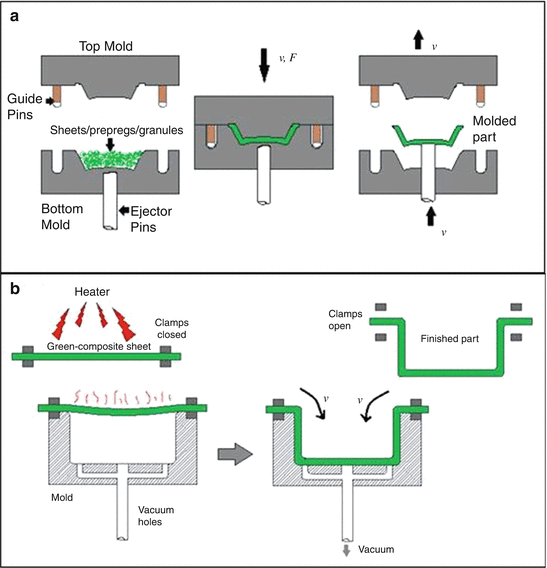

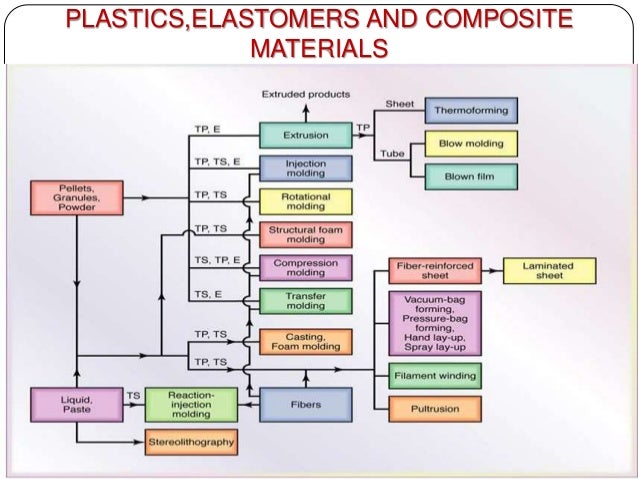

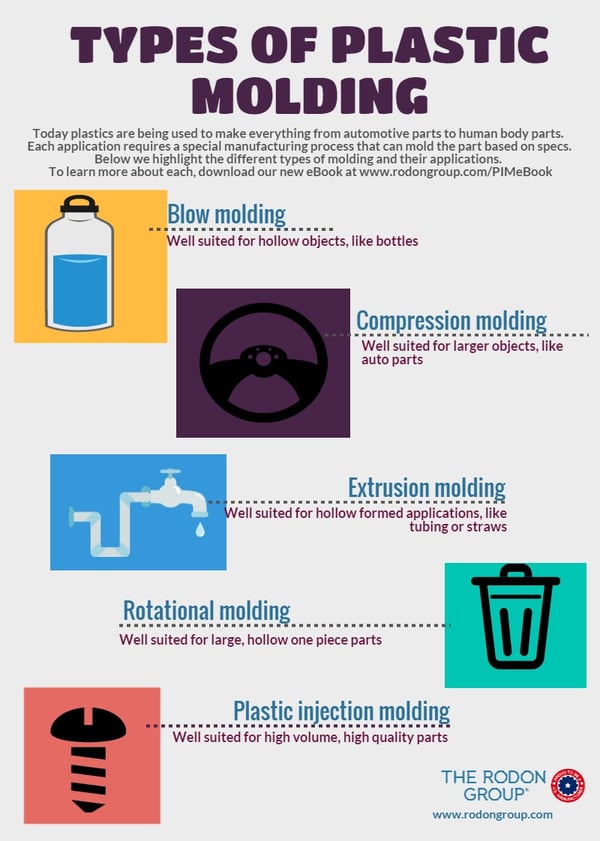

Compression molding plastic sheets. It is mostly used for small parts and products in very high volume. Typically compression molding machines open along a vertical axis. Compression molding is typically employed for low volume production prototyping and evaluation work or in the production of industrial. The heat and pressure cycle of the process will harden the material and then it can be removed.

Once molding is completed excess flash may be removed. The process is someone similar to making waffles. The heat and pressure force the materials into all areas of the mold. Compression molding is accomplished by placing the plastic material can be a granular or pelletized form in a mold cavity to be formed by heat and pressure.

The lower platen contains a recess for the plate or sheet that is charged with resin powder or granules. About 7 of these are plastic sheets. Thermoplastics can be reheated and cooled as much as necessary. A compression molding press consists of two heated platens.

Thermoset plastics and thermoplastics are unique to the compression method of molding. Compression molding is used with thermosetting plastics. Compression molding is a common process used for both thermoplastic and thermoset stock shape materials. Compression molding is a forming process in which a plastic material is placed directly into a heated metal mold then is softened by the heat and therefore forced to conform to the shape of the mold as the mold closes.

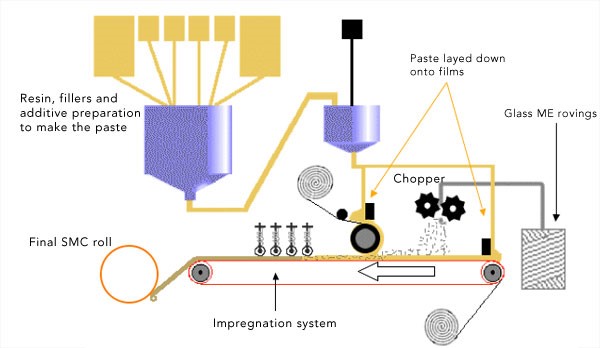

A wide variety of plastic sheets molding options are available to you such as processing service material. Common uses of compression molding the best use of compression molding is the replacement of metal parts with plastic parts. Compression molding is a manufacturing process for stock shapes such as plates or thick sheets fig. The platens are then pressed together and heated to consolidate the resin.

The automotive industry uses compression molding heavily because the final products are very strong and durable. A typical compression molding process is performed at a mold temperature of 350 f and mold pressure of 100.